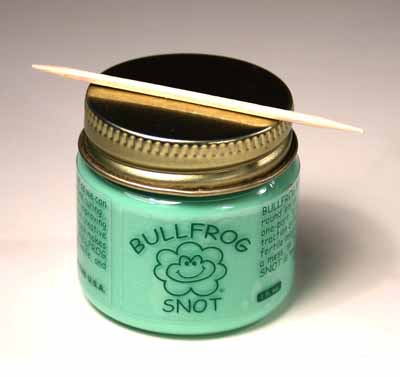

BULLFROG SNOT and suggested installation tool.

Double or Single Bit tools work equally well

as do small brushes, stripwood, twigs, etc...

BULLFROG SNOT is a product and a process.

For true joy, follow these instructions. Please.

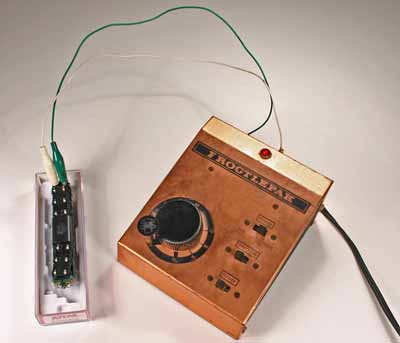

The very basic BULLFROG SNOT work station

... For split frame locos, the chassis is 'hot', so just touching the

frames makes the wheels move...

A drop of BULLFROG SNOT on the installation tool

. . . . . . for HO, S, O use more drops as needed

If you feel the burning desire, BULLFROG SNOT

can be thinned with plain 'ol water.

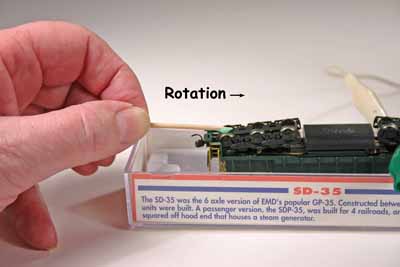

Installing BULLFROG SNOT, just touch it to the

rotating wheel. "Yard speed" works well.

Proper direction of rotation to install BULLFROG SNOT

Do it wrong and you'll get 'clumps' . . . . . .

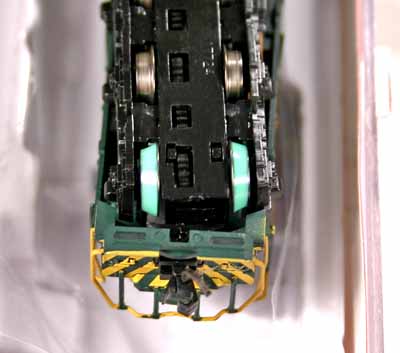

Installing BULLFROG SNOT on a SD-35 *****

Notice that the wheels are 'bare.' BULLFROG SNOT

does not like fresh factory blackened wheels, so

scuff 'em clean or BULLFROG SNOT will not want to stick.

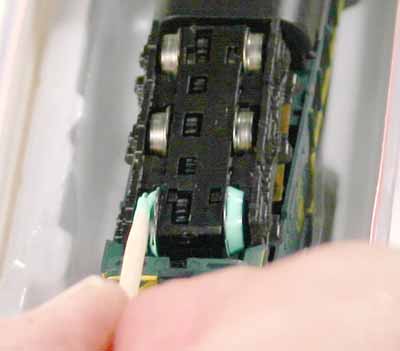

Fresh, properly applied BULLFROG SNOT.

Keep the wheels turning as the BULLFROG SNOT cures,

until the color is gone, maybe 10 minutes or so . . . .

Very important!

Ignore this and gravity will give you a lumpy tire.

Cured BULLFROG SNOT, thin, tight, smooth

Let it fully cure for a few hours, or better; overnight.

Enjoy. It will change the way you run your trains!

Watch the installation video

Installing BULLFROG SNOT is easy.

*Please note: This is a demonstration of before and after BULLFROG SNOT only, it implies nothing (zip, nada, zero) about

the specific performance improvement you may realize on any particular locomotive

Be sure to read the comments attached to the video-viewable on YouTube.

**** To replace a tire missing from a grooved wheel, apply multiple

layers over a period of several days (not all at once) allowing each to fully

cure before proceeding, until the desired level is reached. Check the grip

by on-track testing.

If more conductivity is desired, trim the cured BULLFROG SNOT from

the flange area. Works great for 4-4-0'S, 0-4-0'S, etc...

BULLFROG SNOT

BULLFROG SNOT